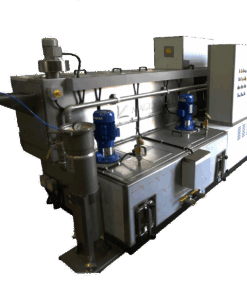

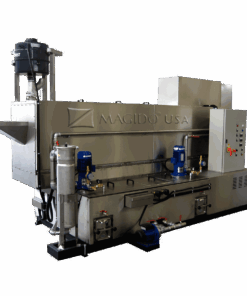

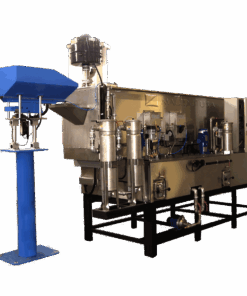

The Spira 2b Series SP640/2 Continuous Feed Rotary Drum 3-stage Parts Washer continuously washes parts as they are feed through the machine by the unique screw-style drum.

(FROM MAGIDO.COM)

These parts washers are designed for the continuous spray washing, using aqueous detergents at a temperature of 60°C maximum. These machines are mainly characterized by the possibility of costantly loading parts on a corrugated conveyor belt, through an operator, a robot, the machine tool or directly integrated into the production line, thanks to its small size. All machines are made of AISI 304 stainless steel and they are models for one wash treatments, with final drying. These machines function thanks to the continuous advancement of the conveyor belt. They’re suitable for washing small, medium and bulky parts. The continuous washing occurs in 2 phases: spray washing and drying.

Compare Spira 2b Series Products |

|

|

|

|

|---|---|---|---|---|

|

Title

|

SP320/2 Continuous Feed Rotary Drum Washer | SP480/2 Continuous Feed Rotary Drum Washer | SP640/2 Continuous Feed Rotary Drum Washer | SP950/2 Continuous Feed Rotary Drum Washer |

|

Description

|

The Spira 2b Series SP320/2 Continuous Feed Rotary Drum 3-stage Parts Washer continuously washes parts as they are feed through the machine by the unique screw-style drum. |

The Spira 2b Series SP480/2 Continuous Feed Rotary Drum 3-stage Parts Washer continuously washes parts as they are feed through the machine by the unique screw-style drum. |

The Spira 2b Series SP640/2 Continuous Feed Rotary Drum 3-stage Parts Washer continuously washes parts as they are feed through the machine by the unique screw-style drum. |

The Spira 2b Series SP950/2 Continuous Feed Rotary Drum 3-stage Parts Washer continuously washes parts as they are feed through the machine by the unique screw-style drum. |

|

Product Link

|

Read more | Read more | Read more | Read more |

|

Model

|

SP320/2 | SP480/2 | SP640/2 | SP950/2 |

|

Weight

|

- | - | - | - |

|

Dimension

|

N/A | N/A | N/A | N/A |

| Specification | Unit | SP210/2 | SP320/2 | SP480/2 | SP640/2 | SP950/2 |

|---|---|---|---|---|---|---|

| Production | CFH | 1,6 | 3,2 | 6,4 | 12,7 | 25 |

| Drum diameter | Inches | 8” | 12" | 19” | 25” | 37” |

| Drum Length | Inches | 106” | 106” | 138” | 138” | 208” |

| Thread pitch | Inches | 4” | 5” | 6” | 8” | 12” |

| Thread depth | Inches | 2” | 2” | 3” | 5” | 10” |

| Diameter holes drum | Inches | 1/5” | 1/5” | 1/5” | 1/5” | 1/5” |

| Loading height | Inches | 50” | 50” | 58” | 58” | 76” |

| Unloading height | Inches | 28” | 28” | 32” | 32” | 32” |

| Wash tank | gal US | 90 | 90 | 130 | 130 | 210 |

| Rinse tank | gal US | 90 | 90 | 130 | 130 | 210 |

| Wash pump | Hp | 3 | 3 | 4 | 4 | 5,5 |

| Wash flow rate pressure | GPM / PSI | 65 / 43 | 65 / 43 | 90 / 43 | 90 / 43 | 105 / 50 |

| Rinse pump | Hp | 3 | 3 | 4 | 4 | 5,5 |

| Rinse flow rate pressure | GPM / PSI | 65 / 43 | 65 / 43 | 65 / 43 | 90 / 43 | 105 / 50 |

| Wash electrical heating | kW | 16 | 16 | 24 | 24 | 32 |

| Rinse electrical heating | kW | 12 | 12 | 18 | 18 | 24 |

| Solution temperature | °F | 100-160 | 100-160 | 100-160 | 100-160 | 100-160 |

| Steam aspirator | HP / CFM | 0.25 / 180 | 0.25 / 180 | 0.25 / 180 | 0.25 / 180 | 0.75 / 470 |

| Electric Drying | kW | 9 | 9 | 15 | 15 | 24 |

| Overall width | Inches | 55” | 55” | 70” | 70” | 80” |

| Overall height | Inches | 75” | 75” | 90” | 90” | 105” |

| Overall depth | Inches | 140” | 140” | 175” | 175” | 255” |

| Power supply | Volt | 460V 3ph 60Hz | 460V 3ph 60Hz | 460V 3ph 60Hz | 460V 3ph 60Hz | 460V 3ph 60Hz |

| PLC | Siemens | Siemens | Siemens | Siemens | Siemens |

We use cookies to improve your experience on our site. By using our site, you consent to cookies.

Manage your cookie preferences below:

Essential cookies enable basic functions and are necessary for the proper function of the website.