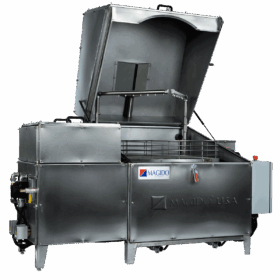

Magido Top Load Aqueous Parts Washers with Rotational Turntable are also referred to as Automatic Jet-Spray Cabinet Washers.

Magido X-51 and X-81 Series parts washers are engineered for automatic spray parts washing applications utilizing aqueous detergents at a temperatures of 150°F. The operation principle is based on a rotating platform on which the parts are placed, and a series of angled water jet nozzles, which optimally wash all the areas of the parts needed to be cleaned.

X-Series wash systems are mainly categorized by the size and capacity of the turntable with sizes ranging from 14” to 55” in diameter. All machines are constructed in AISI 304 stainless steel and additional options are available for filtration, rinsing and drying stages.

Standard Features of our Top Load Parts Washers #

- 304 Stainless Steel Cabinet

- 304 Stainless Steel Centrifugal Pumps

- Incoloy Heating Elements

- Magnetic Float Type Fluid Level Sensors

- Strut Actuated Lid

- Door Safety Switch

- 304 Stainless Steel Turntable

(no sharp metal edges) - 304 Stainless Steel Spray Bars

- V-Jet Nozzles

- Automatic Turntable Drive

(X-51 Series is External) - 304 Stainless Steel Drain Pan & Chip Basket

Eco Series Top Load Spray Cabinet Parts Washing Systems with Rotational Basket #

The ECO parts washer series are designed with a small footpring, making them the ideal solution for small workspaces. Each parts washer is manufactured in 304 stainless steel with an automatic sprocket turntable drive, liquid level sensor, calibrated jet-spray nozzles and tank drain. The Eco series is an affordable alternative to manual parts washing.

Full Specifications Table Eco Series Parts Washers

| Specification | Unit | L800FP | L901FP | L902FP | L922FP |

|---|---|---|---|---|---|

| Automatic Turntable Basket | Standard | Standard | Standard | Standard | |

| Turntable Basket Diameter | Inches | 31” | 35” | 36” | 45” |

| Load Height (from floor) | |||||

| Load Weight | Lbs | 350 lbs | 330 lbs | 330 lbs | 440 lbs |

| Fluid/Tank Capacity | gal US | 22.5 gal | 50 gal | 50 gal | 74 gal |

| Pump | Hp | (1) 1 | (1) 2 | (2) 1 | (2) 2 |

| Flow Rate | GPM | (1) 21 GPM | (1) 21 GPM | (2) 21 GPM | (2) 21 GPM |

| Spray Pressure | PSI | (1) 33 psi | (2) 35 psi | (2) 33 psi | (2) 35 psi |

| Heater | kW | 4 kW | 6 kW | 6 kW | 10 kW |

| Operating Temperature | °F | 140°F | 140°F | 140°F | 140°F |

| Timer | Minute | 0 - 60 | 0 - 60 | 0 - 60 | 0 - 60 |

| Voltage | V | 220/460 | 220/460 | 220/460 | 220/460 |

| Amperage | A | 25/10 | 37/13 | 38/14 | 45/23 |

| Phase | Ph | 1/3 | 1/3 | 1/3 | 3 |

| Length (lid open) | Inches | 45.5” | 51” | 51” | 60” |

| Width | Inches | 45.5” | 53” | 53” | 67” |

| Height (lid open) | Inches | 69” | 78” | 78” | 86” |

| Net Weight | Lbs | 308 lbs | 375 lbs | 441 lbs | 661 lbs |

Magido X-51 Top Load Spray Cabinet Parts Washing Systems with Rotational Basket #

The X-51 Series is designed with a unique clamshell design that brings the jet-spray cleaning power closer to your parts for maximum performance. Each of four models features an automatic rotary turntable, jet-spray cleaning manifolds, adjustable solution heater, complete stainless steel construction, fluid level sensor, removable filter basket and tank drain.

X-51 series parts washers are automatic spray jet wash systems that are constructed using AISI 304 stainless steel and come in 3 models with turntable sizes ranging from 35” to 45”. Each wash system is equipped with a rotating turntable and a spray bar that uses water pressure for washing medium and large-sized parts. The flexibility to adjust the temperature and the wash cycle time are standard features. Additional options for filtration and drying stages are available.

X-51 washers are ergonomic and are engineered to reduce your shop labor cost without sacrificing wash performance. They are ideal for medium workloads with bulky parts and offer ease of operation. Simply load the parts that need to be cleaned on the turntable, the operator starts the automatic cycle and can return to their project rather than washing by hand.

Available Options #

- Steam Exhaust Fan

- Oil Skimmer

- Drain Pump

- Auto Fill

- Bag Filter

- Removable Turntable And Cart

- Fresh Water Rinse

- Heater Dryer

- Air Blow-Off

- Pump Upgrade (58/87 PSI)

- Additional Working Height

- Tank/Cabinet Insulation

Full Specifications Table X51 Series Parts Washers

| X51 Series | unit | L101 | L102 | L122 | L152 |

|---|---|---|---|---|---|

| Turntable Basket Diameter | Inches | 35″ | 35″ | 45″ | 51″ |

| Spray Bars (304 Stainless) | 1 | 2 | 2 | 2 | |

| V-Jet Spray Nozzles (optimized) | 44 | 58 | |||

| Load Weight | Lb | 440 lbs | 440 lbs | 770 lbs | 770 lbs |

| Load Height | in. | 19.5″ (16.5″) | 19.5″ (16.5″) | 27.5″ (24.5″) | 31.5″ (28.5″) |

| Tank Capacity | gal. | 46 gal | 46 gal | 74 gal | 80 gal |

| Flow Rate | GPM | (1) 45 | (2) 29 | (2) 47.5 | (2) 30.5 |

| Spray Pressure | PSI | (1) 34 | (2) 37 | (2) 34 | (2) 35 |

| Pump(s) | hp | 1 x 2 hp | 2 x 1.2 hp | 2 x 2 hp | 2 x 2 hp |

| Heater | kW | 6 | 6 | 10 | 12 |

| Amperage | A | 37/13 | 38/14 | 45/23 | 52/27 |

| Voltage | Volts | 230/460 | 230/460 | 230/460 | 230/460 |

| Phase | Phase | 01/03/25 | 01/03/25 | 3 | 3 |

| Timer | Min | 0 – 60 | 0 – 60 | 0 – 60 | 0 – 60 |

| Max Operating Temperature | °F | 140° | 140° | 140° | 140° |

| Length (lid open) | Inches | 51″ | 51″ | 69″ | 85″ |

| Width | Inches | 48.5″ | 48.5″ | 58.75″ | 70.75″ |

| Height (lid open) | Inches | 78.25″ | 78.25″ | 89″ | 94″ |

| Shipping Dimensions | Inches | L49xW49xH55 | L49xW49xH55 | L63xW59xH71 | L79xW79xH67 |

| Net Weight | Lbs | 310 lbs | 330 lbs | 550 lbs | 830 lbs |

| Pneumatic Lid | – | – | – | Standard | |

| Automatic Turntable Basket | Standard | Standard | Standard | Standard |

X-51/2 Top Load Dual Stage Spray Cabinet Parts Washing Systems with Rotational Basket #

X-51/2 series parts washers are automatic spray jet wash systems with dual tanks for wash and rinse stages that insure a residue free finish. Each washer is constructed using AISI 304 stainless steel and come in 3 models with turntable sizes ranging from 35” to 45”. Wash systems are equipped with a rotating turntable and a spray bar that uses water pressure for washing medium and large-sized parts. The wash and rinse stages are controlled by PLC control operation that prevent cross contamination in the tanks. Additional options for filtration and drying stages are available. The flexibility to adjust the temperature and the wash cycle time is a standard feature.

X-51/2 wash systems are ergonomic and are engineered to reduce your shop labor cost without sacrificing wash performance. They are ideal for medium workloads with bulky parts and offer ease of operation. Simply by loading the parts that need to be cleaned on the turntable, the operator starts the automatic cycle and can return to their task at hand.

The X-51/2 Series is engineered for precision work-cell cleaning applications and features a unique clamshell design that brings the jet-spray cleaning power closer to your parts for maximum performance

Available Options #

- Air Blow-Off

- Additional Working Height

- Bag Filter

- Drain Pump

- Fresh Water Rinse

- Heater Dryer

- Oil Skimmer

- Pump Upgrade (58/87 PSI)

- Removable Turntable with Cart

- Steam Exhaust Fan

Full Specifications Table X51/2 Series Parts Washers

| Specification | unit | L103 | L123 | L153 |

|---|---|---|---|---|

| Turntable Basket Diameter | Inches | 35″ | 45″ | 50″ |

| Load Height | Inches | 19.5″ | 27.5″ | 31.5″ |

| Load Height with Removable Turntable option | Inches | 16.5″ | 24.5″ | 28.5″ |

| Load Weight | Lbs | 440 lbs | 770 lbs | 1,102 lbs |

| Fluid/ WASH Tank Capacity | gal US | 35 gal | 55 gal | 79 gal |

| Fluid/ RINSE Tank Capacity | gal US | 23 gal | 25 gal | 65gal |

| Wash Pump | ||||

| Power | Hp | 1 hp | 1.5 hp | 2 hp |

| Spray Pressure | PSI | 37 psi | 34 psi | 35 psi |

| Flow Rate | GPM | 23 GPM | 45 GPM | 30.5 GPM |

| Rinse Pump | ||||

| Power | Hp | 1 hp | 1.5 hp | 2 hp |

| Spray Pressure | PSI | 35 psi | 35 psi | 35 psi |

| Flow Rate | GPM | 21 GPM | 23 GPM | 30.5 |

| Automatic Turntable Basket Power | Hp | 0.35 hp | 0.5 hp | 0.5 hp |

| Automatic Turntable Basket Speed | Rpm | 7 | 7 | 7 |

| Wash Tank Heater | kW | 6 kW | 10 kW | 12kW |

| Rinse Tank Heater | kW | 4 kW | 4 kW | 8kW |

| Spray Bars (304 Stainless) | 2 | 2 | 2 | |

| V-Jet Spray Nozzles (optimized) | 44 | 58 | 58 | |

| Max Operating Temperature | °F | 140° | 140° | 140° |

| Timer | Minutes | Programmable | Programmable | Programmable |

| PLC | Siemens | Siemens | Siemens | |

| HMI | Weintek | Weintek | Weintek | |

| Voltage | V | 230/460 | 230/460 | 230/460 |

| Amperage | A | TBD | TBD | TBD |

| Phase | 3 | 3 | 3 | |

| Length (lid open) | Inches | 51″ | 72″ | 80.5 |

| Width | Inches | 81” | 90.5” | 118" |

| Height (lid open) | Inches | 78.75″ | 86″ | 95.5" |

| Shipping Dimensions | Inches | L87” x W63” x H45” | L70” x W92” x H75” | L86” x W123” x H65” |

| Net Weight | Lbs | 915 lbs | 1,234 lbs | 1,358 |

X-81 Top Load Spray Cabinet Parts Washing Systems with Rotational Basket #

The MAGIDO X-81Series features a top load design making them the ideal parts washer for your work-cell cleaning applications. Standard features include the automatic rotary turntable, calibrated jet-spray manifold, solution heater, complete stainless steel construction, fluid level control, tank drain and removable filter basket.

Available Options #

- Steam Exhaust Fan

- Oil Skimmer

- Drain Pump

- Auto Fill

- Insulation

Full Specifications Table X81 Series Parts Washers

| Specification | Unit | L-35 | L-55 | L-90 |

|---|---|---|---|---|

| Turntable Basket Diameter | Inches | 15” | 23” | 31” |

| Load Height | Inches | 13.5” | 13.5” | 19.5” |

| Load Weight | Lbs | 155 lbs | 220 lbs | 330 lbs |

| Fluid/Tank Capacity | gal US | 15 gal | 25 gal | 30 gal |

| Pump | Hp | 0.75 hp | 0.75 hp | 1 hp |

| Flow Rate | GPM | 17 GPM | 20 GPM | 24 GPM |

| Spray Pressure | PSI | 37 psi | 35 psi | 35 psi |

| Spray Bar (304 Stainless)* | 1 | 1 | 1 | |

| V-Jet Spray Nozzles (Optimized) | 15 | 15 | 20 | |

| Heater | kW | 2 kW | 3 kW | 4 kW |

| Max Operating Temperature | °F | 140°F | 140°F | 140°F |

| Timer | Minute | 0-60 min | 0-60 min | 0-60 min |

| Manual Lid Shock Supports | 2 | 2 | 2 | |

| Voltage | Volts | 230 | 230/460 | 230/460 |

| Amperage | Amps | 13.6 | 18/6.3 | 20/8.5 |

| Phase | Ph | 1 | 1/3 | 1/3 |

| Length (lid open) | Inches | 26.75” | 34.75” | 46.75” |

| Width | Inches | 29.5” | 34.75” | 42.25” |

| Height (lid open) | Inches | 53.5” | 64.5” | 68.5” |

| Shipping Dimensions | Inches | L30” x W22” x H41” | L36” x W28” x H40” | L45” x W36” x H49” |

| Weight | Lbs | 110 lbs | 130 lbs | 175 lbs |

X51/HP Series #

Standard Features #

- 304 Stainless Steel Cabinet

- 304 Stainless Steel Centrifugal Pump

- Stainless Steel Turntable with Containment Ring

- High Pressure Spray Wand

- Automatic Turntable Drive

- Incaloy Heating Elements

- Magnetic Float Fluid Level Sensor

- Strut Actuated Lid with Lock

- Viewing Window with Air Clearing Manifold

- LED Illuminated Cabinet

- Door Safety Switch

- Stainless Steel Bars

- Stainless Steel Vee-Jet Wash Nozzles

- Isolation Floor with Removable Chip Basket

- Removable Debris Screen

- Tank Drain

Available Options #

- Heated Dryer

- Fresh Water Rinse To Drain (X-51 Series)

- Air Blowoff Cycle

- Heated Dryer

- Filtration

- Oil Water Separator

- Oil Skimmer

- Steam/Mist Collector

- Automatic Water Fill

- 24/7 Programmable Heater Control

- Automatic Chemical Injector

- Removable Turntable With Cart

- Stack Light Tower

- Expanded Working Height

- Pump Upgrade

Safety Features #

- 24V Control Voltage

- NEMA 4 Electrical Panel

- Push Button Emergency Stop

- Rotary Main Power Disconnect Switch

- Safety Overload Protection

- Door Interlock Safety Switch

- Glove Box Interlock Safety Switch

- Locking Counter Balanced Lid

- Liquid Level Shutoff Switch

- High Limit Temperature Sensor

- No Sharp Metal Edges

- Low Noise Operation < 70 dBA

- CE Certified

Full Specifications Table X51HP Series Parts Washers

| Specification | Unit | L101HP | L102HP | L122HP |

|---|---|---|---|---|

| Turntable with Containment Ring | Inches | 35" | 35" | 45" |

| Working Height | Inches | 19.5" | 19.5" | 27.5" |

| Load Weight | Lbs | 440 lbs | 440 lbs | 770 lbs |

| Fluid/Tank Capacity | gal US | 46 gal. | 46 gal. | 74 gal. |

| Pump | GPM | (1) 2-HP 45/34 | (2) 1.5-HP 29/37 | (2) 2-HP 47.5/34 |

| Flow Rate | GPM | (1) 45 GPM | (2) 29 GPM | (2) 47.5 GPM |

| High Pressure Spray Wand | GPM / PSI | 3.7/870 | 3.7/870 | 3.7/870 |

| Jet-Spray Manifold (304 Stainless) | 1 | 2 | 2 | |

| Vee-Jet Wash Nozzles (Optimized) | 22 | 44 | 58 | |

| Heater | kW | 6kW | 6kW | 10kW |

| Max Operating Temperature | °F | 160°F | 160°F | 160°F |

| Timer | Minute | 0-60 min | 0-60 min | 0-60 min |

| Voltage | V | 230/460 | 230/460 | 230/460 |

| Amperage | A | 37/13 | 38/14 | 45/23 |

| Phase | Ph | 1/3 | 1/3 | 3 |

| Weight | Lbs | 419 lbs | 441 lbs | 739 lbs |

| Length (Lid Open) | Inches | 53" | 53" | 73" |

| Width | Inches | 51" | 51" | 73" |

| Height (Lid Open) | Inches | 78.75" | 78.75" | 85.5" |