Stainless Steel Industrial Cleaning Technology #

MAGIDO is recognized as one of the industry’s leading manufacturers of aqueous parts washing systems.

We’ve done so by distinguishing our company with the quality of the products we manufacture. This due to the strategic planning and a careful choice of the quality materials we use during the manufacturing process along with the experience gained over time and the constant search for innovative solutions and technologies that value to our finished product.

Our team is always attentive and willing to help our customers before and after the sales process to ensure total flexibility in creating a tailor-made wash system for their maintenance or production parts washing operation.

DG8 / DG9 Aqueous Parts Washing Systems #

Magido Manual Sink-style Aqueous Parts Washers are engineered to handle the most rigorous challenges that are commonalty found in Industrial-Automotive maintenance parts cleaning applications.

Magido manual parts washers are designed to use environmentally friendly aqueous (water-based) cleaning solutions for safe and effective parts cleaning results.

STANDARD FEATURES #

- Stainless Steel Construction

- External Magnetic Drive Pump

- Flo-Thru Brush

- Electrical Heater Controlled by a Thermostat

- Liquid Level Shut Off

OPTIONS #

- Cartridge filter

- Casters

Full Specifications Table for the DG Series Parts Washers

| Specification | Unit | DG-8 | DG-9 |

|---|---|---|---|

| Working Area | Inches | 33.5” x 19.5 “ | 33.5” x 19.5” |

| Load Weight | Lbs | 300 lbs | 300 lbs |

| Fluid Capacity | gal US | 26.5 gal | 34.5 gal |

| Pump | GPH | 238 GPH | 238 GPH |

| Heater | kW | 2 kW | 2 kW |

| Operating Temperature | °F | 113°F | 113°F |

| Voltage / Amperage | V / A | 115/19 | 115/19 |

| Length | Inches | 37.5” | 37.5” |

| Width | Inches | 19.5” | 19.5” |

| Height | Inches | 43.5" | 43.5" |

| Shipping Dimensions | Inches | 34” x 38” x 43” | 34” x 38” x 43” |

| Net Weight | Lbs | 121 lbs | 132 lbs |

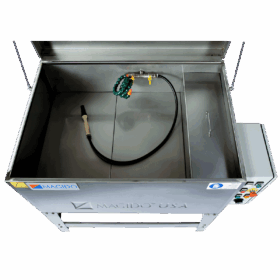

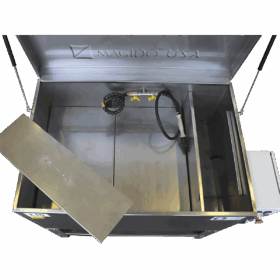

L7 / L10 Aqueous Parts Washing Systems #

Magido Manual Vat-style Aqueous Parts Washers are engineered to handle the most rigorous challenges that are commonalty found in Industrial-Automotive maintenance parts cleaning applications.

Magido manual parts washers are designed to use environmentally friendly aqueous (water-based) cleaning solutions for safe and effective parts cleaning results.

STANDARD FEATURES #

- Stainless Steel Construction

- External Magnetic Drive Pump

- Flo-Thru Brush W/Flexible Spigot

- Removable Work Shelves

- Electrical Heaters Controlled

- By Thermostat

- Liquid Level Shut Off

- Tank Drain L7 L10

OPTIONS #

- list item

Full Specifications Table for the L Series Parts Washers

| Specification | Unit | L-7 | L-10 |

|---|---|---|---|

| Working Area | Inches | L19” x W27.5” | L29.5” x W34” |

| Load Weight | Lbs | 300 lbs | 300 lbs |

| Fluid Capacity | Gal | 24 gal | 40 gal |

| Pump | GPM | 3.5 GPM | 3.5 GPM |

| Heater | kW | 2 kW | 3 kW |

| Operating Temperature | °F | 113°F | 113°F |

| Voltage | Volts | 115 | 115 |

| Amperage | Amps | 19 | 19 |

| Length | Inches | 27” | 35" |

| Width | Inches | 48.5” | 55” |

| Height | Inches | 43” | 43” |

| Shipping Dimensions | Inches | L26” x W48” x H30” | L35” x W54” x H30” |

| Net Weight | Lbs | 155 lbs | 210 lbs |

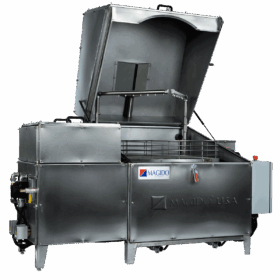

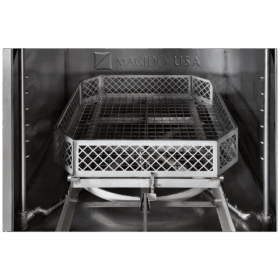

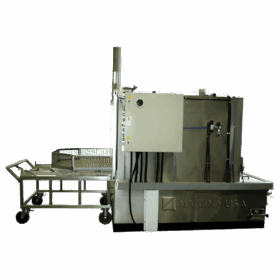

HP25 / HP30 Aqueous Parts Washing Systems #

The HP25 & HP30 parts washers are heated water blasting cabinets made entirely of AISI 304 stainless steel. These wash systems were developled for thechnicians that need to reduce their cleaning time by simply blasting the parts clean with a heated aqueous solution. The high-pressure spray wand capable of delivering up to 840 psi!

STANDARD FEATURES #

- Stainless Steel Construction

- Easy-to-handle Spray Wand

- High Pressure Diaphragm Pump

- Foot Pedal Operation

- Solution Filter

- Hinged Front Door with front Glove Access

- Electrical Heaters Controlled By Thermostat

- Automatic Liquid Level Shut Off

- Removable Work Tray

- Screened Basket Filter

- Large Window With Clearing Blower

- LED Light

- Tank Drain

OPTIONS #

- Auto-Fill

- 24/7 Timer

- Steam Exhaust Fan

- Manual Parts Washer Pump/Brush

- Manual Blow-Off Wand

Full Specifications Table for the HP Series Parts Washers

| Specification | Unit | HP-25 | HP-30 |

|---|---|---|---|

| Working Area | Inches | L23" x W31.5" x H19.5" | L27.5" x W47.5" x H19.5" |

| Working Envelope | L23" x W31.5" x H19.5" | L27.5" x W47.5" x H19.5" | |

| Load Height (from floor) | Inches | 38.5" | 38.5" |

| Load Weight | Lbs | 350 lbs | 350 lbs |

| Fluid Capacity | gal US | 40 gal | 45 gal |

| Flow Rate | GPM | 3.7 GPM | 3.7 GPM |

| Spray Pressure | PSI | 430 - 870 psi | 430 - 870 psi |

| Heater | kW | 3 kW | 4 kW |

| Operating Temperature | °F | 113°F | 113°F |

| Voltage / Amperage | Volts / Amps | 26.5/14 | 31/15.5 |

| Phase | Ph | 1/3+N | 1/3+N |

| Length (lid open) | Inches | 37" | 39" |

| Width | Inches | 45” | 60” |

| Height (lid open) | Inches | 79.5" | 82" |

| Shipping Dimensions | Inches | L 47.5" x W 31.5" x H 83" | L47.5" x W31.5" x H83" |

| Net Weight | Lbs | 319 lbs | 400 lbs |

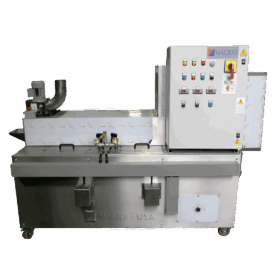

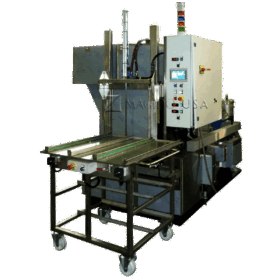

X81 Series Spray Cabinet Parts Washing Systems #

X81 Series parts washers are automatic spray jet wash systems washers that are constructed using AISI 304 stainless steel that are available in 3 models with turntable sizes ranging from 15” to 30”.

Each wash system is equipped with a rotating turntable and a spray bar that uses water pressure for washing small and medium-sized parts.

X81 Washers are engineered to reduce labor cost without sacrificing wash performance and are ideal for work cell cleaning applications.

STANDARD FEATURES #

- Heavy Duty Stainless Steel Construction

- Ergonomic Design

- Swing Away Spray Manifolds

- 60 Minute Timer

- Automatic Turntable Motor

- Solution Filter

- Thermostat Controlled Electrical Heater

- Automatic Liquid Level Shut Off

- Tank Drain

- Low Noise Operation

OPTIONS #

- Oil Skimmer

- Tank Insulation

- Auto Fill

Full Specifications Table for the X81 Series Parts Washers

| Specification | Unit | L-35 | L-55 | L-90 |

|---|---|---|---|---|

| Turntable Basket Diameter | Inches | 15” | 23” | 31” |

| Load Height | Inches | 13.5” | 13.5” | 19.5” |

| Load Weight | Lbs | 155 lbs | 220 lbs | 330 lbs |

| Fluid/Tank Capacity | gal US | 15 gal | 25 gal | 30 gal |

| Pump | Hp | 0.75 hp | 0.75 hp | 1 hp |

| Flow Rate | GPM | 17 GPM | 20 GPM | 24 GPM |

| Spray Pressure | PSI | 37 psi | 35 psi | 35 psi |

| Spray Bar (304 Stainless)* | 1 | 1 | 1 | |

| V-Jet Spray Nozzles (Optimized) | 15 | 15 | 20 | |

| Heater | kW | 2 kW | 3 kW | 4 kW |

| Max Operating Temperature | °F | 140°F | 140°F | 140°F |

| Timer | Minute | 0-60 min | 0-60 min | 0-60 min |

| Manual Lid Shock Supports | 2 | 2 | 2 | |

| Voltage | Volts | 230 | 230/460 | 230/460 |

| Amperage | Amps | 13.6 | 18/6.3 | 20/8.5 |

| Phase | Ph | 1 | 1/3 | 1/3 |

| Length (lid open) | Inches | 26.75” | 34.75” | 46.75” |

| Width | Inches | 29.5” | 34.75” | 42.25” |

| Height (lid open) | Inches | 53.5” | 64.5” | 68.5” |

| Shipping Dimensions | Inches | L30” x W22” x H41” | L36” x W28” x H40” | L45” x W36” x H49” |

| Weight | Lbs | 110 lbs | 130 lbs | 175 lbs |

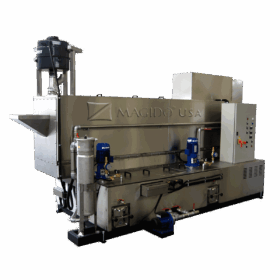

X51 Series Spray Cabinet Aqueous Parts Washing Systems #

X51 Series parts washers are automatic spray jet wash systems that are constructed using AISI 304 stainless steel and are available in 3 models with turntable sizes ranging from 35” to 55”.

Each wash system is equipped with a rotating turntable and a spray bar that uses water pressure for washing medium and large-sized parts.

X51 Washers are ergonomic and engineered to reduce your shop labor cost without sacrificing wash performance. They are ideal for medium workloads with bulky parts and offer ease of operation.

Simply load the parts that need to be cleaned on the turntable, the operator starts the automatic cycle and can return to their project rather than washing by hand.

STANDARD FEATURES #

- Heavy Duty Stainless Steel Construction

- Ergonomic Design

- Swing Away Spray Manifolds

- Programmable Timer

- 2 pumps (L102-L122-L152)

- Solution Filter

- Thermostat Controlled Heater

- Automatic Liquid Level Shut Off

- Tank Drain

- Low Noise Operation

OPTIONS #

- Oil Skimmer

- Tank Insulation

- Auto Fill

- Air Blow-Off Cycle

- Heated and Fresh Water Rinse Cycles

- Filtration Stages

- PLC Touch Screen Control

- Removable Turntable with Rolling Cart

- Automatic Turntable Motor

Full Specifications Table for the X51 Series Parts Washers

| X51 Series | unit | L101 | L102 | L122 | L152 |

|---|---|---|---|---|---|

| Turntable Basket Diameter | Inches | 35″ | 35″ | 45″ | 51″ |

| Spray Bars (304 Stainless) | 1 | 2 | 2 | 2 | |

| V-Jet Spray Nozzles (optimized) | 44 | 58 | |||

| Load Weight | Lb | 440 lbs | 440 lbs | 770 lbs | 770 lbs |

| Load Height | in. | 19.5″ (16.5″) | 19.5″ (16.5″) | 27.5″ (24.5″) | 31.5″ (28.5″) |

| Tank Capacity | gal. | 46 gal | 46 gal | 74 gal | 80 gal |

| Flow Rate | GPM | (1) 45 | (2) 29 | (2) 47.5 | (2) 30.5 |

| Spray Pressure | PSI | (1) 34 | (2) 37 | (2) 34 | (2) 35 |

| Pump(s) | hp | 1 x 2 hp | 2 x 1.2 hp | 2 x 2 hp | 2 x 2 hp |

| Heater | kW | 6 | 6 | 10 | 12 |

| Amperage | A | 37/13 | 38/14 | 45/23 | 52/27 |

| Voltage | Volts | 230/460 | 230/460 | 230/460 | 230/460 |

| Phase | Phase | 01/03/25 | 01/03/25 | 3 | 3 |

| Timer | Min | 0 – 60 | 0 – 60 | 0 – 60 | 0 – 60 |

| Max Operating Temperature | °F | 140° | 140° | 140° | 140° |

| Length (lid open) | Inches | 51″ | 51″ | 69″ | 85″ |

| Width | Inches | 48.5″ | 48.5″ | 58.75″ | 70.75″ |

| Height (lid open) | Inches | 78.25″ | 78.25″ | 89″ | 94″ |

| Shipping Dimensions | Inches | L49xW49xH55 | L49xW49xH55 | L63xW59xH71 | L79xW79xH67 |

| Net Weight | Lbs | 310 lbs | 330 lbs | 550 lbs | 830 lbs |

| Pneumatic Lid | – | – | – | Standard | |

| Automatic Turntable Basket | Standard | Standard | Standard | Standard |

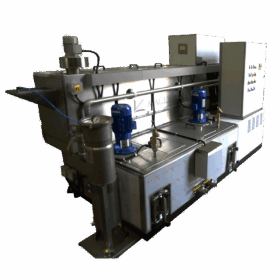

X51/2 Aqueous Parts Washing Systems #

X51/2 Series parts washers are automatic rotational spray jet wash systems with dual tanks for wash and rinse stages that insure a residue free finish.

Each washer is constructed using AISI 304 stainless steel and come in 3 models with turntable sizes ranging from 35” to 55”.

Wash systems are equipped with a rotating turntable and a spray bar that uses water pressure for washing medium and large-sized parts.

The wash and rinse stages are controlled by PLC control operation that prevent cross contamination in the tanks.

X51/2 Wash systems are ergonomic and engineered to reduce your shop labor cost without sacrificing wash performance. They are ideal for medium workloads and offer ease of operation. Simply by loading the parts that need to be cleaned on the turntable, the operator starts the automatic cycle and can return to their task at hand

STANDARD FEATURES #

- Heavy Duty Stainless Steel Construction

- Heated Rinse Stage

- Ergonomic Design

- Swing Away Spray Manifolds

- Freestanding Control Console with PLC Touch Screen Control

- Automatic Turntable Motor

- Solution Filter

- Thermostat Controlled Electrical Heaters

- Automatic Liquid Level Shut Off

- Tank Drain

- Tank Insulation

- Auto Fill

- Low Noise Operation

OPTIONS #

- Oil Skimmer

- Air Blow-Off Cycle

- Filtration Stages

- Removable Turntable with Rolling Cart

- Drain Pump

Full Specifications Table for the X51/2 Series Parts Washers

| Specification | unit | L103 | L123 | L153 |

|---|---|---|---|---|

| Turntable Basket Diameter | Inches | 35″ | 45″ | 50″ |

| Load Height | Inches | 19.5″ | 27.5″ | 31.5″ |

| Load Height with Removable Turntable option | Inches | 16.5″ | 24.5″ | 28.5″ |

| Load Weight | Lbs | 440 lbs | 770 lbs | 1,102 lbs |

| Fluid/ WASH Tank Capacity | gal US | 35 gal | 55 gal | 79 gal |

| Fluid/ RINSE Tank Capacity | gal US | 23 gal | 25 gal | 65gal |

| Wash Pump | ||||

| Power | Hp | 1 hp | 1.5 hp | 2 hp |

| Spray Pressure | PSI | 37 psi | 34 psi | 35 psi |

| Flow Rate | GPM | 23 GPM | 45 GPM | 30.5 GPM |

| Rinse Pump | ||||

| Power | Hp | 1 hp | 1.5 hp | 2 hp |

| Spray Pressure | PSI | 35 psi | 35 psi | 35 psi |

| Flow Rate | GPM | 21 GPM | 23 GPM | 30.5 |

| Automatic Turntable Basket Power | Hp | 0.35 hp | 0.5 hp | 0.5 hp |

| Automatic Turntable Basket Speed | Rpm | 7 | 7 | 7 |

| Wash Tank Heater | kW | 6 kW | 10 kW | 12kW |

| Rinse Tank Heater | kW | 4 kW | 4 kW | 8kW |

| Spray Bars (304 Stainless) | 2 | 2 | 2 | |

| V-Jet Spray Nozzles (optimized) | 44 | 58 | 58 | |

| Max Operating Temperature | °F | 140° | 140° | 140° |

| Timer | Minutes | Programmable | Programmable | Programmable |

| PLC | Siemens | Siemens | Siemens | |

| HMI | Weintek | Weintek | Weintek | |

| Voltage | V | 230/460 | 230/460 | 230/460 |

| Amperage | A | TBD | TBD | TBD |

| Phase | 3 | 3 | 3 | |

| Length (lid open) | Inches | 51″ | 72″ | 80.5 |

| Width | Inches | 81” | 90.5” | 118" |

| Height (lid open) | Inches | 78.75″ | 86″ | 95.5" |

| Shipping Dimensions | Inches | L87” x W63” x H45” | L70” x W92” x H75” | L86” x W123” x H65” |

| Net Weight | Lbs | 915 lbs | 1,234 lbs | 1,358 |

X53 Aqueous Parts Washing Systems #

Magido X53 Series parts washers are engineered for automatic spray parts washing applications utilizing aqueous detergents at a temperatures of 160°F.

The operation principle is based on a fixed platform on which the parts are placed, and a series of angled water jet nozzles that are configured on a spray ramp to optimally wash all the areas of the parts needed to be cleaned.

X53 Series wash systems are mainly categorized by the size and capacity of the turntable with sizes up to 59”x59” in diameter. The turntable removes easily from the wash system on to a mobile cart for easy loading and unloading. All machines are constructed in AISI 304 stainless steel with additional options available for filtration, rinsing and drying.

STANDARD FEATURES #

- Heavy Duty Stainless Steel Construction

- PLC Touch Screen Control

- Ergonomic Design

- 60 Minute Timer

- Automatic Turntable Motor

- Thermostat Controlled Electrical Heater

- Automatic Liquid Level Shut Off

- Tank Drain

- Tank Insulation

- Auto Fill

- Exhaust Fan

- Low Noise Operation

- Removable Turntable with Rolling Cart

OPTIONS #

- Oil Skimmer

- Air Blow-Off Cycle

- Heated and Fresh Water Rinse Cycles

- Filtration Stages

Full Specifications Table for the X53 Series Parts Washers

| Specification | unit | L160 | L190 | L210 | L240 |

|---|---|---|---|---|---|

| Turntable Basket | Inches | 43” x 43” | 51” x 51” | 59” x 59” | 71” x 71” |

| Load Height | Inches | 31.5” | 35.5” | 39” | 39” |

| Load Weight | Lbs | 1,500 lbs | 1,500 lbs | 1,500 lbs | 1,500 lbs |

| Fluid/Tank Capacity | gal US | 77 gal | 103 gal | 132 gal | 185 gal |

| Pump(s) | Hp | 7.5 psi | 10 psi | 10 psi | 10 psi |

| Flow Rate | GPM | 132 GPM | 145 GPM | 145 GPM | 145 GPM |

| Spray Pressure | PSI | 58 psi | 65 psi | 65 psi | 65 psi |

| Heater | kW | 20 kW | 30 kW | 30 kW | 36 kW |

| Max Operating Temperature | °F | 160° | 160° | 160° | 160° |

| Voltage | V | 460 V-60 Hz | 460 V-60 Hz | 460 V-60 Hz | 460 V-60 Hz |

| Phase | Ph | 3 | 3 | 3 | 3 |

| HMI | Weintek | Weintek | Weintek | Weintek | |

| PLC | Siemens | Siemens | Siemens | Siemens | |

| Overall Dimensions (door closed) | Inches | L82” x W63” x H91.5” | L90.5” x W72” x H91.5” | L98.5” x W80” x H99.5” | L111” x W92” x H99.5” |

| Overall Dimensions (door open) | Inches | L82” x W63” x H116” | L90.5” x W72” x H116” | L98.5” x W80” x H132” | L111” x W92” x H132” |

| Net Weight | Lbs | 2,048 | 2,481 | 2,590 | 2,866 |

X53/2 Aqueous Parts Washing Systems #

Magido X53/2 Series parts washers are engineered for automatic spray parts washing applications utilizing aqueous detergents at a temperatures of 160°F. The operation principle is based on a fixed platform on which the parts are placed, and a series of angled water jet nozzles that are configured on a spray ramp to optimally wash all the areas of the parts needed to be cleaned.

X53/2 Series wash systems are mainly categorized by the size and capacity of the turntable with sizes up to 59”x59” in diameter. The turntable removes easily from the wash system on to a mobile cart for easy loading and unloading. All machines are constructed in AISI 304 stainless steel with additional options available for filtration, rinsing and drying stages.

STANDARD FEATURES #

- Heavy Duty Stainless Steel

- Construction

- PLC Touch Screen Control

- Ergonomic Design

- 60 Minute Timer

- Automatic Turntable Motor

- Thermostat Controlled Electrical Heater

- Automatic Liquid Level Shut Off

- Tank Drain

- Tank Insulation

- Auto Fill

- Exhaust Fan

- Low Noise Operation

- Removable Turntable with Rolling Cart

OPTIONS #

- Oil Skimmer

- Air Blow-Off Cycle

- Heated and Fresh Water Rinse Cycles

- Filtration Stages

- Increase weight capacity up to 5,000 lbs

Full Specifications Table for the X53/2 Series Parts Washers

| Specification | unit | L103 | L123 | L153 |

|---|---|---|---|---|

| Turntable Basket Diameter | Inches | 35″ | 45″ | 50″ |

| Load Height | Inches | 19.5″ | 27.5″ | 31.5″ |

| Load Height with Removable Turntable option | Inches | 16.5″ | 24.5″ | 28.5″ |

| Load Weight | Lbs | 440 lbs | 770 lbs | 1,102 lbs |

| Fluid/ WASH Tank Capacity | gal US | 35 gal | 55 gal | 79 gal |

| Fluid/ RINSE Tank Capacity | gal US | 23 gal | 25 gal | 65gal |

| Wash Pump | ||||

| Power | Hp | 1 hp | 1.5 hp | 2 hp |

| Spray Pressure | PSI | 37 psi | 34 psi | 35 psi |

| Flow Rate | GPM | 23 GPM | 45 GPM | 30.5 GPM |

| Rinse Pump | ||||

| Power | Hp | 1 hp | 1.5 hp | 2 hp |

| Spray Pressure | PSI | 35 psi | 35 psi | 35 psi |

| Flow Rate | GPM | 21 GPM | 23 GPM | 30.5 |

| Automatic Turntable Basket Power | Hp | 0.35 hp | 0.5 hp | 0.5 hp |

| Automatic Turntable Basket Speed | Rpm | 7 | 7 | 7 |

| Wash Tank Heater | kW | 6 kW | 10 kW | 12kW |

| Rinse Tank Heater | kW | 4 kW | 4 kW | 8kW |

| Spray Bars (304 Stainless) | 2 | 2 | 2 | |

| V-Jet Spray Nozzles (optimized) | 44 | 58 | 58 | |

| Max Operating Temperature | °F | 140° | 140° | 140° |

| Timer | Minutes | Programmable | Programmable | Programmable |

| PLC | Siemens | Siemens | Siemens | |

| HMI | Weintek | Weintek | Weintek | |

| Voltage | V | 230/460 | 230/460 | 230/460 |

| Amperage | A | TBD | TBD | TBD |

| Phase | 3 | 3 | 3 | |

| Length (lid open) | Inches | 51″ | 72″ | 80.5 |

| Width | Inches | 81” | 90.5” | 118" |

| Height (lid open) | Inches | 78.75″ | 86″ | 95.5" |

| Shipping Dimensions | Inches | L87” x W63” x H45” | L70” x W92” x H75” | L86” x W123” x H65” |

| Net Weight | Lbs | 915 lbs | 1,234 lbs | 1,358 |

Rotary Drum Aqueous Parts Washing Systems #

Magido industrial rotary-auger drum wash systems are the right choice for your continuous parts cleaning process. In the cleaning operation parts are augured through the machines processing drum and cleaned by a dual action process that combines both submersion that flushes inside of hollow parts and spray cleaning action that cleans the exterior. Each wash system is customized to your exact specifications and typical process zones may include prewash, wash, rinse, rust prevention, blow-off and drying stages.

STANDARD FEATURES #

- All stainless steel construction

- Standard rotary drum diameter ranging from 8”-37”

- Standard rotary drum length ranging from 67”-208”

- Wash/Rinse/Dry

- Heated, insulated wash and rinse tanks

OPTIONS #

- Oil Skimmer

- Automatic water fill

- Automatic drain pump for tanks

- PLC Controlled

- Bag filtration

- Oil coalescing system

Full Specifications Table Jolly Series for the Rotary Drum Parts Washers

| Specification | Unit | J210 | J320 | J210/2 | J320/2 |

|---|---|---|---|---|---|

| Production | CFH | 0.7 | 1.4 | 0.7 | 1.4 |

| Drum diameter | Inches | 8” | 12" | 8” | 12" |

| Drum Length | Inches | 47” | 47” | 71” | 71” |

| Thread pitch | Inches | 4” | 5” | 4” | 5” |

| Thread depth | Inches | 2” | 2” | 2” | 2” |

| Diameter holes drum | Inches | 1/5” | 1/5” | 1/5” | 1/5” |

| Loading height | Inches | 35” | 35” | 35” | 35” |

| Unloading height | Inches | 21” | 21” | 21” | 21” |

| Wash tank | gal US | 27 | 27 | 27 | 27 |

| Rinse tank | gal US | - - | - - | 27 | 27 |

| Wash pump | Hp | 0.75 | 0.75 | 0.75 | 0.75 |

| Wash flow rate pressure | GPM / PSI | 21 / 30 | 21 / 30 | 21 / 30 | 21 / 30 |

| Wash electrical heating | kW | 8 | 8 | 8 | 8 |

| Solution temperature | °F | 100-140 | 100-140 | 100-140 | 100-140 |

| Steam aspirator | HP / CFM | 0.12 / 60 | 0.12 / 60 | 0.12 / 60 | 0.12 / 60 |

| Overall width | Inches | 32” | 32” | 42” | 42” |

| Overall height | Inches | 54” | 54” | 65” | 65” |

| Overall depth | Inches | 65” | 65” | 90” | 90” |

| Power supply | Volt | 460V 3ph 60Hz | 460V 3ph 60Hz | 460V 3ph 60Hz | 460V 3ph 60Hz |

| PLC | Siemens | Siemens | Siemens | Siemens |

Full Specifications Table for the Spira 1b Series Rotary Drum Parts Washers

| Specification | Unit | SP210 | SP320 | SP480 | SP640 | SP950 |

|---|---|---|---|---|---|---|

| Production | CFH | 1,6 | 3,2 | 6,4 | 12,7 | 25 |

| Drum diameter | Inches | 8” | 12" | 19” | 25” | 37” |

| Drum Length | Inches | 67” | 67” | 98” | 98” | 150” |

| Thread pitch | Inches | 4” | 5” | 6” | 8” | 12” |

| Thread depth | Inches | 2” | 2” | 3” | 5” | 10” |

| Diameter holes drum | Inches | 1/5” | 1/5” | 1/5” | 1/5” | 1/5” |

| Loading height | Inches | 50” | 50” | 58” | 58” | 76” |

| Unloading height | Inches | 28” | 28” | 32” | 32” | 32” |

| Wash tank | gal US | 90 | 90 | 130 | 130 | 210 |

| Wash pump | Hp | 3 | 3 | 4 | 4 | 5,5 |

| Wash flow rate pressure | GPM / PSI | 65 / 43 | 65 / 43 | 90 / 43 | 90 / 43 | 105 / 50 |

| Wash electrical heating | kW | 16 | 16 | 24 | 24 | 32 |

| Solution temperature | °F | 100-160 | 100-160 | 100-160 | 100-160 | 100-160 |

| Steam aspirator | HP / CFM | 0.25 / 180 | 0.25 / 180 | 0.25 / 180 | 0.25 / 180 | 0.75 / 470 |

| Electric Drying | kW | 9 | 9 | 15 | 15 | 24 |

| Overall width | Inches | 55” | 55” | 65” | 65” | 80” |

| Overall height | Inches | 75” | 75” | 90” | 90” | 105” |

| Overall depth | Inches | 100” | 100” | 140” | 140” | 200” |

| Power supply | Volt | 460V 3ph 60Hz | 460V 3ph 60Hz | 460V 3ph 60Hz | 460V 3ph 60Hz | 460V 3ph 60Hz |

| PLC | Siemens | Siemens | Siemens | Siemens | Siemens |

Full Specifications Table for the Spira 2b Series Rotary Drum Parts Washers

| Specification | Unit | SP210/2 | SP320/2 | SP480/2 | SP640/2 | SP950/2 |

|---|---|---|---|---|---|---|

| Production | CFH | 1,6 | 3,2 | 6,4 | 12,7 | 25 |

| Drum diameter | Inches | 8” | 12" | 19” | 25” | 37” |

| Drum Length | Inches | 106” | 106” | 138” | 138” | 208” |

| Thread pitch | Inches | 4” | 5” | 6” | 8” | 12” |

| Thread depth | Inches | 2” | 2” | 3” | 5” | 10” |

| Diameter holes drum | Inches | 1/5” | 1/5” | 1/5” | 1/5” | 1/5” |

| Loading height | Inches | 50” | 50” | 58” | 58” | 76” |

| Unloading height | Inches | 28” | 28” | 32” | 32” | 32” |

| Wash tank | gal US | 90 | 90 | 130 | 130 | 210 |

| Rinse tank | gal US | 90 | 90 | 130 | 130 | 210 |

| Wash pump | Hp | 3 | 3 | 4 | 4 | 5,5 |

| Wash flow rate pressure | GPM / PSI | 65 / 43 | 65 / 43 | 90 / 43 | 90 / 43 | 105 / 50 |

| Rinse pump | Hp | 3 | 3 | 4 | 4 | 5,5 |

| Rinse flow rate pressure | GPM / PSI | 65 / 43 | 65 / 43 | 65 / 43 | 90 / 43 | 105 / 50 |

| Wash electrical heating | kW | 16 | 16 | 24 | 24 | 32 |

| Rinse electrical heating | kW | 12 | 12 | 18 | 18 | 24 |

| Solution temperature | °F | 100-160 | 100-160 | 100-160 | 100-160 | 100-160 |

| Steam aspirator | HP / CFM | 0.25 / 180 | 0.25 / 180 | 0.25 / 180 | 0.25 / 180 | 0.75 / 470 |

| Electric Drying | kW | 9 | 9 | 15 | 15 | 24 |

| Overall width | Inches | 55” | 55” | 70” | 70” | 80” |

| Overall height | Inches | 75” | 75” | 90” | 90” | 105” |

| Overall depth | Inches | 140” | 140” | 175” | 175” | 255” |

| Power supply | Volt | 460V 3ph 60Hz | 460V 3ph 60Hz | 460V 3ph 60Hz | 460V 3ph 60Hz | 460V 3ph 60Hz |

| PLC | Siemens | Siemens | Siemens | Siemens | Siemens |

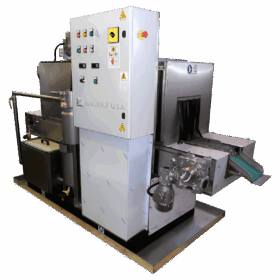

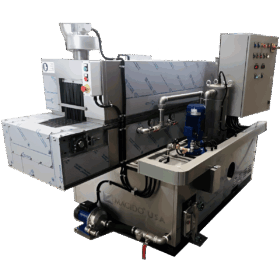

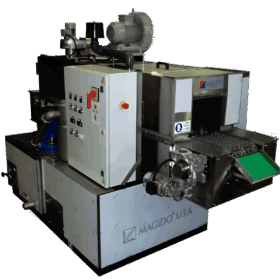

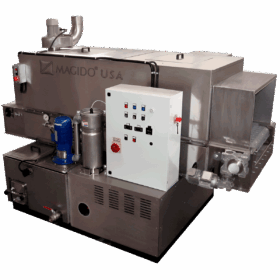

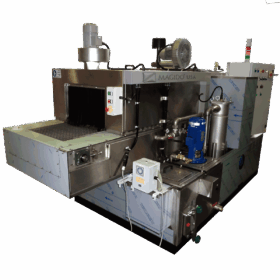

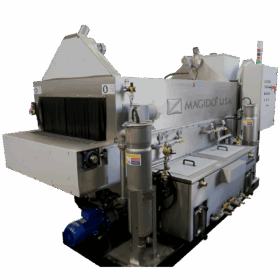

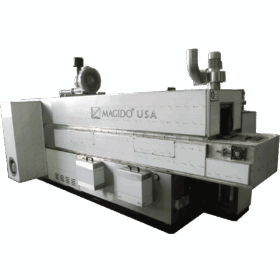

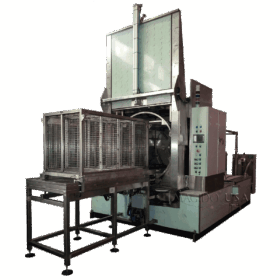

In-Line Belt Conveyor Aqueous Parts Washing Systems #

Magido industrial in-line belt conveyor wash systems are the right choice for your flow-through cleaning process. Each wash system is customized to your exact specifications and typical process zones may include pre-wash, wash, rinse, rust prevention, blow-off and drying stages.

In addition, Magido in-line parts washers are designed to use environmentally safe aqueous (water-based) cleaning solutions for parts cleaning applications. Inline Belt Conveyor Wash Systems

STANDARD FEATURES #

- All stainless steel construction

- Standard belt conveyor width

ranging from 8”-39” - Standard belt conveyor width length

ranging from 120”-180” - Wash/Rinse/Dry

- Heated, insulated wash and rinse tanks

OPTIONS #

- Oil Skimmer

- Automatic water fill

- Automatic drain pump for tanks

- PLC Controlled

- Bag filtration

- Oil coalescing system

Full Specifications Table for the Siver Series In-Line Belt Conveyor Parts Washers

| Specification | Unit | S200 | S300 | S400 |

|---|---|---|---|---|

| Available width of conveyor belt | Inches | 8" | 12" | 16" |

| Usable washing height | Inches | 12" | 12" | 12" |

| Real load | lb/yd | 100 | 100 | 100 |

| Conveyor belt speed | fpm | 0.7-3.3 | 0.7-3.3 | 0.7-3.3 |

| Loading height | Inches | 32" | 32" | 32" |

| Wash Tank | gal US | 40 | 40 | 40 |

| Wash Pump | Hp | 1,2 | 1,2 | 1,2 |

| Wash flow rate Pressure | GPM / PSI | 32 / 36 | 32 / 36 | 32 / 36 |

| Wash electrical heating | Kw/m | 12 | 12 | 12 |

| Solution temperature | F | 100-140 | 100-140 | 100-140 |

| Steam aspirature | Hp / CFM | 0.25 180 | 0.25 180 | 0.25 180 |

| Electrical drying | Inches | 9 | 9 | 9 |

| Overall width | Inches | 47” | 47” | 47” |

| Overall height | Inches | 70” | 70” | 70” |

| Overall depth | Inches | 106” | 106” | 106” |

| Power supply | Inches | 460V / 3Ph +N / 60Hz | 460V / 3Ph +N / 60Hz | 460V / 3Ph +N / 60Hz |

| PLC | Siemens | Siemens | Siemens | Siemens |

Full Specifications Table for the Gold 1b Series In-Line Belt Conveyor Parts Washers

| Specification | Unit | G200 | G300 | G400 | G500 | G600 | G700 | G800 | G900 | G1000 |

|---|---|---|---|---|---|---|---|---|---|---|

| Width of Conveyor belt | Inches | 8" | 12" | 16" | 20" | 23" | 27" | 31" | 35" | 39" |

| Usable washing height | Inches | 10” | 10” | 10” | 14” | 14” | 14” | 14” | 14” | 14” |

| Real load | lb/yd | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Conveyor belt speed | fpm | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

| Loading height | Inches | 40" | 40" | 40" | 40" | 40" | 40" | 40" | 40" | 40" |

| Wash Tank | gal US | 90 | 90 | 90 | 120 | 120 | 120 | 140 | 140 | 140 |

| Rinse Tank | gal US | - | - | - | - | - | - | - | - | - |

| Wash Pump | Hp | 3 | 3 | 3 | 4 | 4 | 4 | 5,5 | 5,5 | 5,5 |

| Wash flow rate Pressure | GPM / PSI | 50 / 43 | 50 / 43 | 50 / 43 | 80 / 50 | 80 / 50 | 80 / 50 | 90 / 60 | 90 / 60 | 90 / 60 |

| Rinse pump | Hp | - | - | - | - | - | - | - | - | - |

| Rinse flow rate - pressure | GPM/PSI | - | - | - | - | - | - | - | - | - |

| Wash electrical heating | Kw/m | 18 | 18 | 18 | 24 | 24 | 24 | 30 | 30 | 30 |

| Rinse electrical heating | Kw/m | - | - | - | - | - | - | - | - | - |

| Solution temperature | F | 100-160 | 100-160 | 100-160 | 100-160 | 100-160 | 100-160 | 100-160 | 100-160 | 100-160 |

| Steam aspirature | Hp / CFM | 0.25 180 | 0.25 180 | 0.25 180 | 0.75 470 | 0.75 470 | 0.75 470 | 0.75 470 | 0.75 470 | 0.75 470 |

| Electrical drying | Inches | 12 | 12 | 12 | 15 | 15 | 15 | 18 | 18 | 18 |

| Overall width | Inches | 70” | 70” | 70” | 85” | 85” | 85” | 95” | 95” | 95” |

| Overall height | Inches | 70” | 70” | 70” | 80” | 80” | 80” | 85” | 85” | 85” |

| Overall depth | Inches | 120” | 120” | 120” | 120” | 120” | 120” | 120” | 120” | 120” |

| Power supply | Volt | 460V / 3Ph/ 60Hz | 460V / 3Ph/ 60Hz | 460V / 3Ph/ 60Hz | 460V / 3Ph/ 60Hz | 460V / 3Ph/ 60Hz | 460V / 3Ph/ 60Hz | 460V / 3Ph/ 60Hz | 460V / 3Ph/ 60Hz | 460V / 3Ph/ 60Hz |

| PLC | Siemens | Siemens | Siemens | Siemens | Siemens | Siemens | Siemens | Siemens | Siemens |

Full Specifications Table for the Gold 2b Series In-Line Belt Conveyor Parts Washers

| Specification | Unit | G200/2 | G300/2 | G400/2 | G500/2 | G600/2 | G700/2 | G800/2 | G900/2 | G1000/2 |

|---|---|---|---|---|---|---|---|---|---|---|

| Available width of conveyor belt | Inches | 8" | 12" | 16" | 20" | 23" | 27" | 31" | 35" | 39" |

| Usable washing height | Inches | 10” | 10” | 10” | 14” | 14” | 14” | 14” | 14” | 14” |

| Real load | lb/yd | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Conveyor belt speed | fpm | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

| Loading height | Inches | 40" | 40" | 40" | 40" | 40" | 40" | 40" | 40" | 40" |

| Wash Tank | gal US | 90 | 90 | 90 | 120 | 120 | 120 | 140 | 140 | 140 |

| Rinse Tank | gal US | 90 | 90 | 90 | 120 | 120 | 120 | 140 | 140 | 140 |

| Wash Pump | Hp | 3 | 3 | 3 | 4 | 4 | 4 | 5,5 | 5,5 | 5,5 |

| Wash flow rate Pressure | GPM / PSI | 50 / 43 | 50 / 43 | 50 / 43 | 80 / 50 | 80 / 50 | 80 / 50 | 90 / 60 | 90 / 60 | 90 / 60 |

| Rinse pump | Hp | 3 | 3 | 3 | 4 | 4 | 4 | 5,5 | 5,5 | 5,5 |

| Rinse flow rate - pressure | GPM / PSI | 50 / 43 | 50 / 43 | 50 / 43 | 80 / 50 | 80 / 50 | 80 / 50 | 90 / 60 | 90 / 60 | 90 / 60 |

| Wash electrical heating | Kw/m | 18 | 18 | 18 | 24 | 24 | 24 | 30 | 30 | 30 |

| Rinse electrical heating | Kw/m | 12 | 12 | 12 | 16 | 16 | 16 | 18 | 18 | 18 |

| Solution temperature | F | 100-160 | 100-160 | 100-160 | 100-160 | 100-160 | 100-160 | 100-160 | 100-160 | 100-160 |

| Steam aspirature | Hp / CFM | 0.25 180 | 0.25 180 | 0.25 180 | 0.75 470 | 0.75 470 | 0.75 470 | 0.75 470 | 0.75 470 | 0.75 470 |

| Electrical drying | Inches | 12 | 12 | 12 | 15 | 15 | 15 | 18 | 18 | 18 |

| Overall width | Inches | 70” | 70” | 70” | 85” | 85” | 85” | 95” | 95” | 95” |

| Overall height | Inches | 70” | 70” | 70” | 80” | 80” | 80” | 85” | 85” | 85” |

| Overall depth | Inches | 180” | 180” | 180” | 180” | 180” | 180” | 180” | 180” | 180” |

| Power supply | Volt | 460V / 3Ph / 60Hz | 460V / 3Ph / 60Hz | 460V / 3Ph / 60Hz | 460V / 3Ph / 60Hz | 460V / 3Ph / 60Hz | 460V / 3Ph / 60Hz | 460V / 3Ph / 60Hz | 460V / 3Ph / 60Hz | 460V / 3Ph / 60Hz |

| PLC | Siemens | Siemens | Siemens | Siemens | Siemens | Siemens | Siemens | Siemens | Siemens |

Rotary Immersion Aqueous Parts Washing Systems #

Magido’s industrial rotary-immersion style wash systems are the right choice for your work cell parts cleaning process. In the cleaning operation the parts washer cleans parts in baskets or fixtures by rotating them in a turbulent immersion parts washing bath combined with a spray cleaning cycle. The cleaning cycle is followed by a combination of spray and immersion rinsing with an available stage for drying. Each wash system is customized to your exact specifications.

Magido rotary-immersion parts washers are designed to use environmentally safe aqueous (water-based) cleaning solutions for safe and effective parts cleaning applications.

STANDARD FEATURES #

- All stainless steel construction

- Heated, insulated wash and rinse tanks

- Wash/Rinse/Dry

OPTIONS #

- Oil Skimmer

- Automatic water fill

- Automatic drain pump for tanks

- PLC Controlled

- Bag filtration

- Oil coalescing system

Full Specifications Table for the Platinum Series Rotary Immersion Parts Washers

| Specification | Unit | PM400 | P600/2 | P900/2 | P1200/2 | P1500/2 |

|---|---|---|---|---|---|---|

| Basket Dimensions | Inches | L24” x W12” x H12” | L35” x W15” x H15” | L47” x W19” x H19” | L59” x W31” x H34” | |

| Load Weight | Lbs | 440 lbs | 770 lbs | 1100 lbs | 1500 lbs | |

| Wash Fluid Capacity | gal US | 130 gal | 210 gal | 320 gal | 660 Gal. | |

| Wash Pump | Hp / PSI / GPM | 4 Hp / 60 psi / 65 GPM | 4 Hp / 60 psi / 65 GPM | 5.5 Hp / 60 psi / 90 GPM | 5.5 Hp / 60 psi / 90 GPM | |

| Wash Heater | kW | 18 kW | 24 kW | 30 kW | 60 kW | |

| Rinse Fluid Capacity | gal US | 65 gal | 105 gal | 130 gal | 210 gal | |

| Rinse Pump | HP / PSI / GPM | 5.5 Hp / 60 psi / 90 GPM | 5.5 Hp / 60 psi / 90 GPM | 5.5 Hp / 60 psi / 90 GPM | 7.5 Hp / 60 psi / 130 GPM | |

| Rinse Heater | kW | 12 kW | 16 kW | 18 kW | 24 kW | |

| Steam Exhaust | ¼ Hp / 60 cfm | ½ HP / 180 cfm | ½ HP / 180 cfm | ¾ HP / 470 cfm | ||

| PLC | Siemens | Siemens | Siemens | Siemens | Siemens | |

| HMI | Weintek | Weintek | Weintek | Weintek | Weintek | |

| Load Height | Inches | 36” | 40” | 40” | 44” | |

| Drum Rotation | ¼ Hp | ¾ Hp | 1 Hp | 1 Hp | ||

| Rotation Speed | Rpm | 1-3 RPM | 0.6-2.2 RPM | 0.6-2.2 RPM | 0.5-1.8 RPM | |

| Machine Dimensions | L110” x W67” x H95” | L140” x W70” x H110” | L165” x W75” x H120” | L235” x W100” x H165” | ||

| Voltage | 460V/3PH/60 Hz | 460V/3PH/60 Hz | 460V/3PH/60 Hz | 460V/3PH/60 Hz |

Applications #

The MAGIDO® parts washers are designed to solve the particular washing needs of small, medium and large parts, in small, medium and large series, and are made for the following industries:

- Aeronautical

- Automotive industry

- Industrial

- Marine

- Military

- Rail Road