At Magido we have developed some of the very best aqueous parts cleaning systems on earth!

Choosing the right parts washer depends on the specific cleaning needs of your parts and the industry you are in.

To choose a parts washing system, you need to consider several factors that align with your specific application and requirements.

- First, understand the type of contaminants you need to remove, as this will influence the type of cleaning solution and system needed.

- Next, determine the desired level of cleanliness, which can vary depending on the industry and application.

- Consider the size, shape, and configuration of the parts you need to clean, as well as their weight and material composition. This will help you select a system that can accommodate these characteristics effectively.

- Additionally, evaluate the volume of parts you need to clean, as this will impact the system’s capacity and the number of loads you need to handle.

- The type of cleaning fluid is also crucial. Aqueous solutions are suitable for water-based contaminants, while solvent-based solutions are better for oil-based contaminants.

- Furthermore, decide on the level of automation required, as automated systems can save labor and increase efficiency, especially in high-throughput environments.

- Finally, consider the environmental regulations and goals in your area, as these can affect the choice of cleaning fluids and the overall system design.

By addressing these factors, you can select a parts washing system that meets your specific needs and ensures efficient and effective cleaning.

Types of Parts Washers and their Primay Functions

The type of part washer you'll need is determined by what you are cleaning.

Here are some types of parts washers that might suit your needs:

-

Cabinet Parts Washers:

Self-contained units with a cabinet or enclosure where parts are loaded for cleaning. They are useful for environments where containment of cleaning solutions is necessary.

-

Green Parts Washers (Biomatic):

Offer an environmentally friendly method for cleaning parts. In these systems, parts are placed in a heated washer containing a pH-neutral solution with a colony of microorganisms that break down grime on the parts.

-

In-Line Belt Conveyor Washers

Designed for the continuous spray washing of constantly loaded parts on a corrugated conveyor belt, through an operator, a robot, the machine tool or directly integrated into the production line.

-

Immersion Parts Washers:

These involve submerging parts in a tank filled with a cleaning solution. They are suitable for parts that can be fully submerged and do not have complex geometries.

-

Manual Parts Washers:

Designed for the manual washing of parts using a foot pedal regulated flow-through hand-held Brush powered by an aqueous solution. These washers can be sink top or clam shell with gloves.

-

Rotary Parts Washers:

Feature a rotating turntable or drum that holds the parts. As the turntable rotates, the parts come into contact with the cleaning solution, ensuring thorough coverage and cleaning of the parts' surfaces.

-

Ultrasonic Parts Washers:

Utilize ultrasonic vibrations to create tiny bubbles in the cleaning solution, which agitate and dislodge contaminants from parts' surfaces. They are effective for cleaning intricate or delicate parts.

Important! Consider the type of parts you need to clean, their size, complexity, and the level of contamination.

Also, think about the industry standards and regulations you must adhere to when selecting a parts washer

AUTOMATIC SPRAY JET AQUEOUS PARTS WASHING SYSTEM

An automatic spray jet wash system is a machine that uses high-pressure water jets to thoroughly clean items by automatically spraying them with a cleaning solution from multiple nozzles, typically on a rotating turntable, with minimal manual intervention, allowing for efficient cleaning of large quantities of parts or components in a controlled environment; essentially, it’s a mechanized cleaning process where water jets are directed at the items to be cleaned, often with automated controls for the cleaning cycle and solution delivery.

Key Points - Automatic Spray Jet Parts Washing Systems

- AUTOMATED OPERATION: Once loaded, the system automatically cycles through the cleaning process, including spraying, rinsing, and sometimes drying, without requiring constant manual operation.

- HIGH-PRESSURE JETS: Powerful water jets provide deep cleaning by forcefully removing dirt and debris from surfaces.

- ROTATING TURNTABLE: Many systems utilize a rotating turntable to ensure all surfaces of the items are exposed to the cleaning spray.

- CLEANING SOLUTION: The system can be designed to use various cleaning solutions depending on the materials and types of dirt being cleaned.

- INDUSTRIAL APPLICATIONS: Commonly used in manufacturing settings to clean parts like automotive components, machine parts, and metal piece

MANUAL OPERATION AQUEOUS PARTS WASHING SYSTEMS

A manual parts washer is a cleaning system where a user manually cleans parts by hand, typically using a brush or spray nozzle, in a tank filled with a solvent or water-based cleaning solution to remove contaminants like grease, oil, and dirt, often used in industrial and automotive settings where parts need to be cleaned without automated processes; essentially, it’s a “sink-on-a-drum” with a brush for scrubbing parts manually.

Key Points - Manual Parts Washing Systems

- HAND OPERATED: The user is responsible for physically scrubbing and manipulating the parts within the cleaning solution.

- BASIC DESIGN: Often consists of a simple tank with a cleaning fluid, allowing for soaking or manual brushing of parts.

- SUITABLE FOR SMALL-SCALE CLEANING: Ideal for cleaning small batches of parts or for situations where intricate cleaning requires manual attention.

- COMMON APPLICATIONS: Automotive repair shops, maintenance facilities, small manufacturing operation

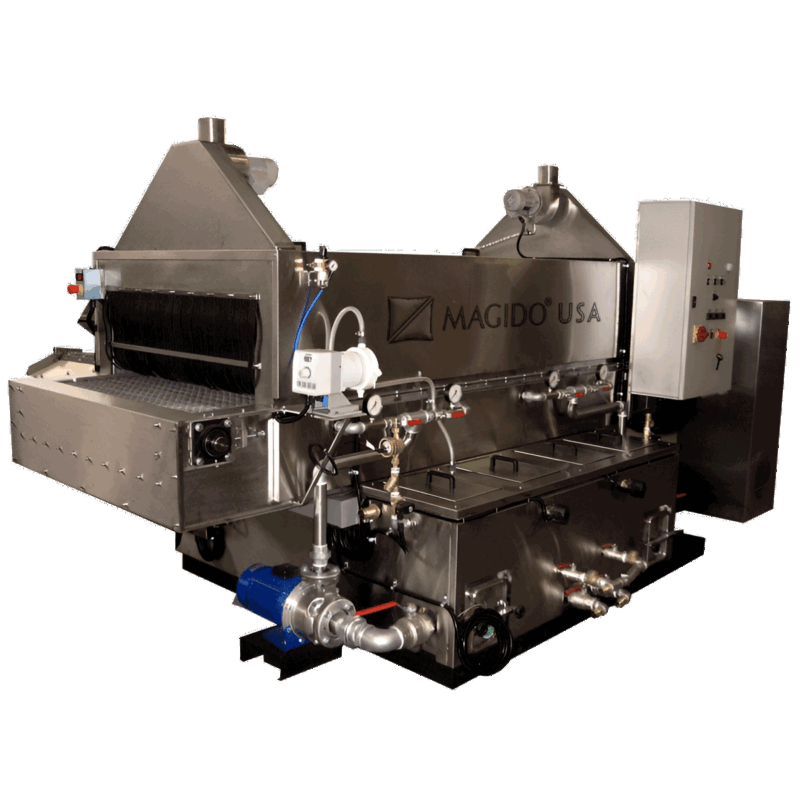

IN-LINE BELT CONVEYOR AQUEOUS PARTS WASHING SYSTEMS

An “In-Line Belt Conveyor Washer” is a machine that continuously cleans parts by moving them along a conveyor belt through a series of washing stages, such as pre-wash, wash, rinse, and dry, all in a single, uninterrupted flow, allowing for high-volume cleaning of parts within a production line without stopping the conveyor belt; essentially, it’s a conveyor system designed specifically to clean parts while they are being transported along the belt without needing to be manually handled or removed from the conveyor system.

Key Points - In-Line Belt Conveyor Wash Systems

- CONTINUOUS MOVEMENT: Parts are loaded onto the conveyor belt and move through the cleaning stages automatically, ensuring consistent cleaning throughout the process.

- MULTIPLE CLEANING ZONES: The system includes different cleaning zones, such as spraying with cleaning solutions, rinsing with water, and potentially drying stages, depending on the specific needs.

- INTEGRATED WITH PRODUCTION LINE: This system is designed to be directly integrated into an existing production line, allowing parts to be cleaned without interrupting the workflow.

- CLEANING EFFICIENCY: The automated process helps to achieve consistent and thorough cleaning while minimizing manual labor.

Typical components of In-line belt conveyor parts washing systems

- Conveyor belt: The moving belt that transports the parts through the cleaning stages.

- Cleaning spray nozzles: Sprayers positioned strategically to deliver cleaning solutions onto the parts.

- Rinse nozzles: Sprayers for rinsing off cleaning solution residue.

- Drainage system: To collect and remove dirty cleaning solutions.

- Control panel: To manage cleaning parameters like spray pressure, cleaning solution flow, and cycle time.

Applications of in-line belt conveyor parts washing systems:

- Automotive industry: Cleaning car parts like engine components, chassis parts, and body panels.

- Manufacturing industries: Cleaning metal parts, plastic components, and other machined parts.

- Electronics manufacturing: Cleaning printed circuit boards and electronic components.

HELICAL / ROTARY DRUM AQUEOUS PARTS WASHING SYSTEM

A Rotary Drum Parts Cleaning System is an automated industrial cleaning machine that uses a rotating drum to continuously clean small parts by tumbling them while spraying them with a cleaning solution, ensuring all surfaces are thoroughly exposed and cleaned effectively; it’s ideal for high-volume, continuous cleaning processes of components like fasteners, bearings, and stamped parts.

Helical drum parts washers are a valuable asset for businesses requiring efficient and thorough cleaning of parts, ensuring high production rates and maintaining the integrity of the components.

KEY POINTS - Rotary Immersion Parts Cleaning Systems

- ROTATING DRUM: The central component is a cylindrical drum that rotates, allowing parts to tumble inside while being sprayed with cleaning solution.

- INTERNAL HELIX: Most rotary drums have an internal helix that helps move the parts through the drum as it rotates, ensuring all surfaces are exposed.

- DRUM with SCREW: The machine features a long, horizontal drum with an internal helical screw advances and tumbles the parts, ensuring that all surfaces are exposed to the cleaning solution.

- CLEANING STAGES: The system can be designed with multiple cleaning stages, including washing, rinsing, and drying, with separate solutions for each stage.

- CONTINUOUS FEEDING: Parts are continuously fed into the drum, allowing for high-volume cleaning.

- CONTINUOUS LOADING: Parts can be continuously loaded into the drum, either manually by an operator, through a loader, or directly from a machine tool. This continuous process is ideal for high-volume production environments.

- APPLICATIONS: Automotive industry, Aerospace industry, Metal forming industries, Ammunition manufacturing, and Fastener production.

- AQUEOUS DETERGENTS: The cleaning process uses aqueous detergents at a temperature of up to 70°C. The combination of spray and immersion washing ensures thorough cleaning, even in hard-to-reach areas.

- MATERIAL CONSTRUCTION: All machines are typically made of AISI 304 stainless steel, which promotes longevity and resistance to corrosion.

Cleaning Process

- Spray and Immersion Washing: The parts are subjected to both spray and immersion washing. The spray washes oils, dust, and debris from the exterior, while immersion ensures that any hollow areas or blind holes are thoroughly cleaned.

- Multi-Stage Cleaning: Helical drum parts washers can be designed as single or multi-stage systems. Common stages include washing, rinsing, and drying. Some models may also include additional stages such as sealing or passivation.

- Drying: After the washing and rinsing stages, the parts are dried using a regenerative air-knife blower and heated dryer. This ensures that the parts are clean and dry before they are discharged from the machine.

Benefits

- Efficiency: The continuous loading and unloading process, combined with the multi-stage cleaning system, ensures high efficiency and productivity.

- Automation: Many helical drum parts washers are fully automated, reducing the need for manual intervention and freeing up technicians to focus on other tasks.

- Customization: These machines can be customized to meet specific production needs, including drum size, helix pitch, and additional cleaning stages.

Applications

- Industrial and Manufacturing: Helical drum parts washers are widely used in various industries, including automotive, aerospace, ammunition, and metalworking. They are particularly suitable for cleaning small to medium parts with intricate geometries.

- High-Volume Production: These machines are ideal for high-volume production environments where continuous cleaning is required. They can handle thousands of parts per hour, making them a cost-effective solution for large-scale operations.

- Delicate Parts Handling: Despite the tumbling action, helical drum parts washers are designed to handle delicate parts with care, ensuring that the cleaning process does not cause damage.

Contact Your Magido USA Representative Today!

Schedule an appointment, request more information, get a quote, get answers…

Contact Your Magido USA Representative Today!

Schedule an appointment, request more information, get a quote, get answers…